SWEETWOODS lignin new value-chain

SWEETWOODS biorefinery lignin has entered a new value-chain through the BBI JU flagship project VIOBOND.

SWEEDWOODS leading partner Graanul Biotech is the partner supplying different lignin qualities to the VIOBOND consortium for the development of a new lignin phenol-formaldehyde resin plant. The project aims to replace fossil-derived materials with bio-based alternatives in the production of furniture, floor coverings, thermal insulation, sandpaper and other everyday products. The project combines knowledge and experience in lignin, wood processing, energy, engineering and other fields of scientific research and industrial production.

For more information read the VIOBOND press release: The VIOBOND consortium will replace fossil resources with renewable lignin in everyday consumer products

High purity lignin

SWEETWOODS project IBN production scale-up

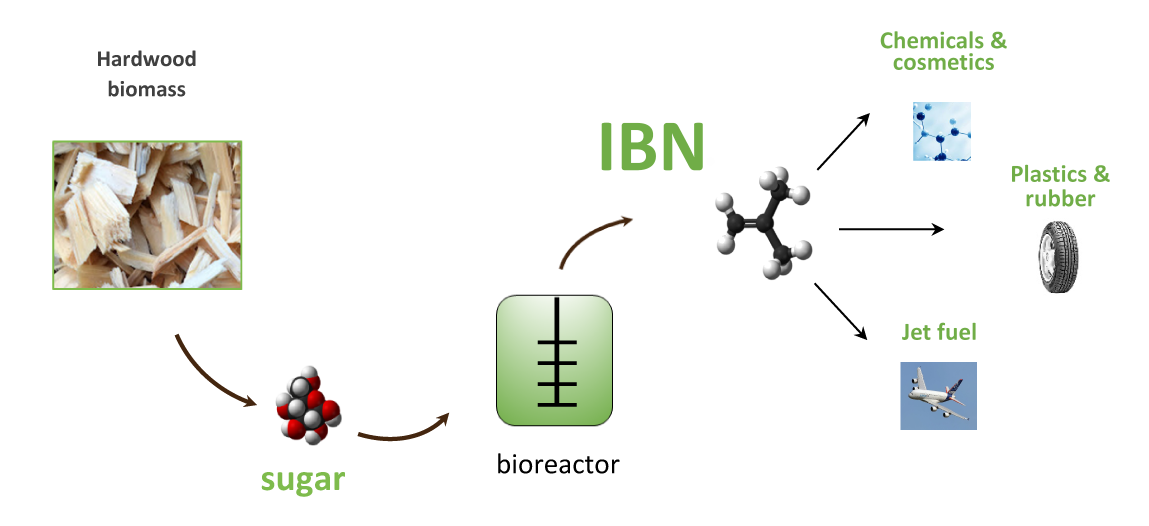

SWEETWOODS project partners Global Bioenergies and Graanul Biotech have initiated demo scale IBN fermentation production campaigns.

The Bio-Based Industries Joint Undertaking (BBI JU) funded SWEETWOODS project partners Global Bioenergies and Graanul Biotech have been collaborating since 2018 with the common goal of establishing a first of a kind high yield isobutene (IBN) production from cellulosic sugars process. Since the start of the project continuous progress has been achieved on both cellulosic sugars production by Graanul Biotech and IBN bioprocess side by Global Bioenergies.

The SWEETWOODS novel fractionation flagship uses sustainable hardwood residues to demonstrate, on an industrial scale, how novel pre-treatment technology in combination with tailored enzymatic solutions can provide high-quality wood sugars and hydrolytic lignin. Graanul Biotech has successfully started up the wood fractionation flagship plant first phase and is now producing cellulosic sugars at the ton scale.

As the mild pre-treatment process applied in the demo plant is very fast and highly controllable Graanul Biotech is able to produce cellulosic sugars with high purity and low inhibitory profiles. The cellulosic sugars can be concentrated up to 60-70% range without viscosity and crystallization issues – this means that they can substitute dextrose up to 100% even in more demanding fermentation processes.

The high quality of the sugar translates into top fermentation performances for the production of IBN. Global Bioenergies has tested the new cellulosic sugars at lab scale and pilot scale and found that they promote biomass growth and allow for high productivity of IBN. The consortium has now initiated demo scale IBN production campaigns.

“The use of 2nd generation substrates is essential for the production of large quantities of IBN to replace fossil-based materials in a range of products from jet fuels to cosmetics. Our partnership with Graanul Biotech has shown that wood-derived sugars can be produced with the right properties at an industrially relevant scale,“ said Global Bioenergies senior project leader Nicolas Barraud.

“We have been collaborating with Global Bioenergies for quite some time now and I am very impressed by the unique fermentation process delivering such good results on our sugars. Looking forward to completing the next steps and realizing the 2nd generation sugar to IBN route on an industrial scale one day, “ commented Graanul Biotech´s product manager Karl Peebo.

The SWEETWOODS consortium, led by Graanul Biotech, brings together innovation-oriented partners: Global Bioenergies, Tecnaro, Armacell, Recticel, MetGen, 2B Srl and Spinverse. The SWEETWOODS project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 792061.

- For more information on the quality and availability of cellulosic sugars please contact: karl.peebo@graanulinvest.com

- For more information on cellulosic IBN contact: nicolas.barraud@global-bioenergies.com

SWEETWOODS delivers first tons of high purity lignin and wood sugars

The flagship of SWEETWOODS has reached its first milestones with industrially representative samples of high purity lignin and wood sugars available at the ton scale for testing at novel value chains.

The Bio-Based Industries Joint Undertaking (BBI JU) funded SWEETWOODS wood valorisation flagship is now ready to ship out industrially representative samples of high purity near-native lignin and wood sugars at the ton scale. The project’s leading partner Graanul Biotech has stated that the first phase construction works of the flagship were finished in 2020 and that the construction of the second phase, where hydrolysis, separation processes, and lignin drying will be established, has started. Graanul Biotech estimates that an industrial supply of novel lignin and sugars will be available the last quarter of 2022.

The SWEETWOODS novel fractionation demo plant uses sustainable hardwood biomass to demonstrate, on an industrial scale, how novel pre-treatment technology in combination with innovative enzymatic solutions can provide high-quality lignin and wood sugars. This unique technology converts over 90% of hardwood into usable high-quality feedstocks for biomaterials and biochemicals and enables establishing novel bio-based value chains with a low ecological footprint.

‘The whole fractionation process still needs to be challenged within 24/7 operation at scale, but preliminary performance tests have had very promising results yielding expected high purity lignin and sugars. This means that we have created a strong basis for near term realisation of supply of sustainable feedstocks for different biomaterials and biochemicals production to create industry-changing new value chains, where wood as sustainable raw material plays a vital role.” said Graanul Biotech’s R&D Manager Dr Peep Pitk.

High purity lignin and wood sugars in evaluation

One of the goals of the SWEETWOODS project is to establish markets for lignin and sugar-based platform chemicals. The consortium partner Tecnaro, which develops and produces thermoplastic compounds, composites and blends, confirms that high-purity lignin from the SWEETWOODS project can be used as a substitute for conventional lignin in biocomposite production, offering improved product quality without odour.

‘These first tests show positive results that novel high purity lignin will allow Tecnaro to enter higher value markets and gain competitive advantage through both sustainability and performance,’ said Dr Michael Schweizer from Tecnaro. The Tecnaro product family includes ARBOFORM®, which is made from 100% renewable raw materials and is biodegradable.

SWEETWOODS consortium member Recticel is currently evaluating on lab scale which (depolymerised) lignin types are most suitable for incorporation in rigid foam for insulation boards. The most suitable candidates will be further upscaled and screened on a semi-industrial scale.

Another consortium partner Global Bioenergies has successfully scaled up the production of bio-isobutene from residual wood derived sugars at the ton scale. The company is also progressing very well towards the commercialisation of renewable cosmetics with the first EU registration of a key cosmetic-grade ingredient derived from fermentative isobutene.

An important part of the SWEETWOODS project is to evaluate the environmental and socio-economic performance of the SWEETWOODS plant, feedstock, and of the developed products. The consortium member 2B has been working on the Life Cycle Assessment (LCA) of the whole wood fractionation process to calculate the environmental impact of the outputs of this process: sugar concentrates and lignin. The LCA has allowed the identification of the environmental hotspots of the fractionation process, which are useful in an eco-design perspective. The LCA results are currently being compared with other biorefining processes and products to get a numeric estimate of the environmental benefits of the SWEETWOODS flagship technology.

The SWEETWOODS consortium, led by Graanul Biotech, brings together innovation-oriented partners: Global Bioenergies, Tecnaro, Armacell, Recticel, MetGen, 2B Srl and Spinverse.

This SWEETWOODS project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 792061.

SWEETWOODS flagship

SWEETWOODS project is progressing as planned

SWEETWOODS consortium had a productive review meeting in Brussels at the beginning of March where external experts took a closer look at our progress and confirmed that SWEETWOODS project is on track.

SWEETWOODS project periodic report for the first 18 months was accepted by the BBI JU. With the first 18 months a lot of progress with novel lignin and cellulosic sugars applications has been made.

As of today, SWEETWOODS flagship plant construction works have been finished and key equipment installation is nearly completed.

Although due to COVID-19 pandemics delivery of certain equipment and instruments have been delayed, nevertheless all preparations are in place to start with commissioning as soon as pandemic related restrictions allow.

Flagship plant in Estonia, Imavere

SWEETWOODS shared insights at projects fair and Stakeholder Forum

The SWEETWOODS project shared its updates and progress at BBI JU Stakeholder Forum and projects exhibition event in Brussels on the 3rd and 4th of December 2019.

Bio-based industry community was brought together to facilitate open discussion on the impact, achievements and strategic direction of the BBI JU programme, as well as the latest developments in the bio-based industries sector.

On the 3rd of December the projects event was held with 100 BBI JU granted projects that showcased technologies, processes and products and their concrete added value in everyday lives. Bringing 100 granted projects together in one venue allowed the participants to network with the project representatives and facilitate the exchange of ideas and knowledge.

SWEETWOODS project was represented by leading partner Graanul Biotech R&D Manager Peep Pitk and consortium member Metgen CEO Alex Michine.

On the 4th of December BBI JU Stakeholder Forum main event took place with a comprehensive programme of high-level speakers. Among other great speakers was the SWEETWOODS leading partner Graanul Invest CEO Raul Kirjanen who talked about the need to have stable policies for bioeconomy development.

Flagship plant received the cornerstone

On Tuesday, 17 September, Graanul Invest sub-company Graanul Biotech laid the cornerstone for wood processing flagship plant.

The purpose of the flagship plant, which will be constructed on the territory of Graanul Invest in Estonia is development and production of biomaterials from low-quality wood residues. In result of temperature, pressure and mechanical force, the innovative technology of the plant splits wood fibers into basic elements – high-purity lignin and wood sugars, which enable use in several industries.

Research and development manager of Graanul Invest Group Peep Pitk provided an overview, how the idea and search of technologies reached construction and cornerstone ceremony in three and a half years. „For years, we have searched a technology, which would provide maximum efficiency coefficient in wood processing, while having as low environmental impact and ecological footprint as possible. Today we believe that the selected technology provides these expected solutions, but we will see the real results only when the flagship plant is completed and processes are operating,“ said Pitk. According to his words, the estimated time of completion of the first stage of the flagship plant is the first half of 2020.

The SWEETWOODS project supporting the construction of the flagship plant has received research financing, which is one of the largest in Estonia and one of the most influential in the EU – Bio-Based Industries Joint Undertaking is supporting the project with 20.96 million euros.

Technology licence of the flagship plant comes from Sweetwater Energy, engineering is done by De Smet Engineers & Contractors from Belgium, special parts of the preliminary project and main project were designed by Sweco Projekt AS, and constructive design of the production building was drafted by Maru Ehitus AS. Main contractor of the construction is Maru Ehitus AS.

The capsule was set in the cornerstone of the plant by member of the management board of Graanul Invest Raul Kirjanen, research and development manager Peep Pitk and Järva rural municipality mayor Rait Pihelgas.

The time capsule included a cup with high purity lignin, pre-fractionated woodchips that are raw material for the plant, business plan of the project, foundation articles of Graanul Biotech and the newspaper of the day.

Peep Pitk, Raul Kirjanen, Rait Pihelgas.

SWEETWOODS flagship plant construction work starts in July

Estonian rural municipality government has issued a building permit for the wood valorisation flagship plant to be established by Graanul Biotech, subsidiary of Graanul Invest. Construction work on the industrial demo plant is planned to start in July.

One-of-a-kind flagship plant that will be established in Imavere uses hardwood residues as raw material and turns biomass into biomaterials with innovative characteristics – high-purity lignin and wood sugars. The new biomaterials offer sustainable solution for many different industries – from chemistry and food industry to cosmetics and construction materials.

“We are delighted that Imavere as the heart of Estonian wood industry is growing into a globally important centre of wood valorisation,” said Raul Kirjanen, CEO of Graanul Invest. “15 years ago, the story of Graanul Invest started with the first plant in Imavere, and now an innovative industrial demo plant that allows for the research and development to move to the next level in wood valorisation is in the process of being built next to that same plant.”

Imavere to the world map

“The development of entrepreneurship is important for Järva rural municipality, and we are glad that new jobs are being created in the Imavere area. What’s important about the project is that it’s a test plant and research work that is sure to take Imavere to the world map once the goals are achieved,” said Rait Pihelgas, Järva rural municipality mayor.

Järva rural municipality government supports the undertaking and, at the same time, is considering the effect the demo plant will have on the environment and the population of Imavere when introducing all the new technologies. “According to the preliminary assessment, we believe that the living environment of Imavere will in no way deteriorate due to the establishment of the flagship plant,” said Pihelgas.

According to Peep Pitk, Head of Research and Development at Graanul Invest group, innovative processing of wood provides the opportunity to move from a resource-based wood industry model to a knowledge-based model for developing innovative bioprocesses and novel materials. The demo plant technology has been developed with target to have a minimal ecological footprint and low impact on the environment, which allows dimensioning the plant size according to local conditions.

“The location of Imavere precisely between two leading research centres in Estonia creates good opportunities for broad cooperation with Estonian universities in order to create a globally important wood valorisation centre of excellence in Imavere, which brings together the world’s top science of wood processing and industry practices,” said the Head of Research and Development Pitk.

The demo plant is part of the SWEETWOODS project that has received research financing that is one of the largest in Estonia and one of the most influential in the EU – Bio-Based Industries Joint Undertaking is supporting the project with 20.96 million euros.

SWEETWOODS project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 792061.

SWEETWOODS explained in 3 minutes

We are happy to share an animation video about the SWEETWOODS project!

The animation was put together in cooperation with all the partners to explain the basis of the project.

The first part of the three minute video explains what the project is about and the second part offers more information about the innovative process we are using to produce high purity lignin and wood sugars.

The animation is made with simple visual langue that makes it easily understandable for wider audience, says Karit Kaasik who is responsible for the communication of the SWEETWOODS project. “As we are really trying to create a change with the SWEETWOODS it is important that people understand what we are doing and why it is so important.”

The SWEETWOODS project aims to create innovation in wood industry

Nine European bio-innovation companies have joined forces to establish a first-of-a-kind wood fractionation Flagship plant to create new industrial value-chains using sustainable hardwood as a resource.

The project was selected under the name SWEETWOODS, in the frame of the European HORIZON 2020 programme for research and innovation, following a very selective and competitive process led by independent experts.

The SWEETWOODS project covers a total budget of €43.2 million. Non-refundable grants totaling €20.96 million will be provided by the EU, with the remainder being contributed by the SWEETWOODS project participants.

On the 9th of May the consortium announced the signature of a grant agreement and this intense 4-year cooperation made official start with kick-off meeting on the 1st of June 2018.

The 9 participants of the SWEETWOODS project representing 6 EU-member States have signed an agreement with the Bio-Based Industries Joint Undertaking (BBI JU) to demonstrate at the industrial level successful and profitable production of high purity lignin and sugars. They aim to demonstrate these materials in novel applications by combining the technologies and know-how of participants as follows:

- Industrial wood processing competence by OÜ Graanul Biotech

- Industrial enzymes for hydrolysis, lignin depolymerization, and sugar conversions by MetGen Oy

- Post-processing of lignin for bio-composites production by Tecnaro GmbH

- Production of bio-based elastomeric foams by Armacell, viaUltima GmbH

- Incorporation of lignin into polyurethane foams production by Recticel N.V.

- Hydrolysate fermentation to bio-isobutene by Global Bioenergies

- Life Cycle Assessment of the project by 2B Srl

- Viability performance analysis by Vertech Group

- Project management support by Spinverse Oy

SWEETWOODS consortium kick-off meeting in Tallinn 01.06